An air compressor can be defined as a machine which compresses the air and increases its pressure by reducing the volume. The air compressor sucks air from the atmosphere, compresses it and delivers it at high pressure to a storage vessel. From the storage vessel, the compressed air can be distributed through pipelines to the required place. Since, the compressor of air requires some work to be done on it, therefore a compressor must be driven by some external device or prime mover.

Table of Contents

Uses of Compressed Air

- For supercharging and scavenging of Internal Combustion Engines.

- For producing blast of air in blast furnaces.

- In the operation of lifts, pumps, rams etc.

- For cleaning of complicated castings.

- For operating pneumatic drills, riveters, road drills, paint spraying etc.

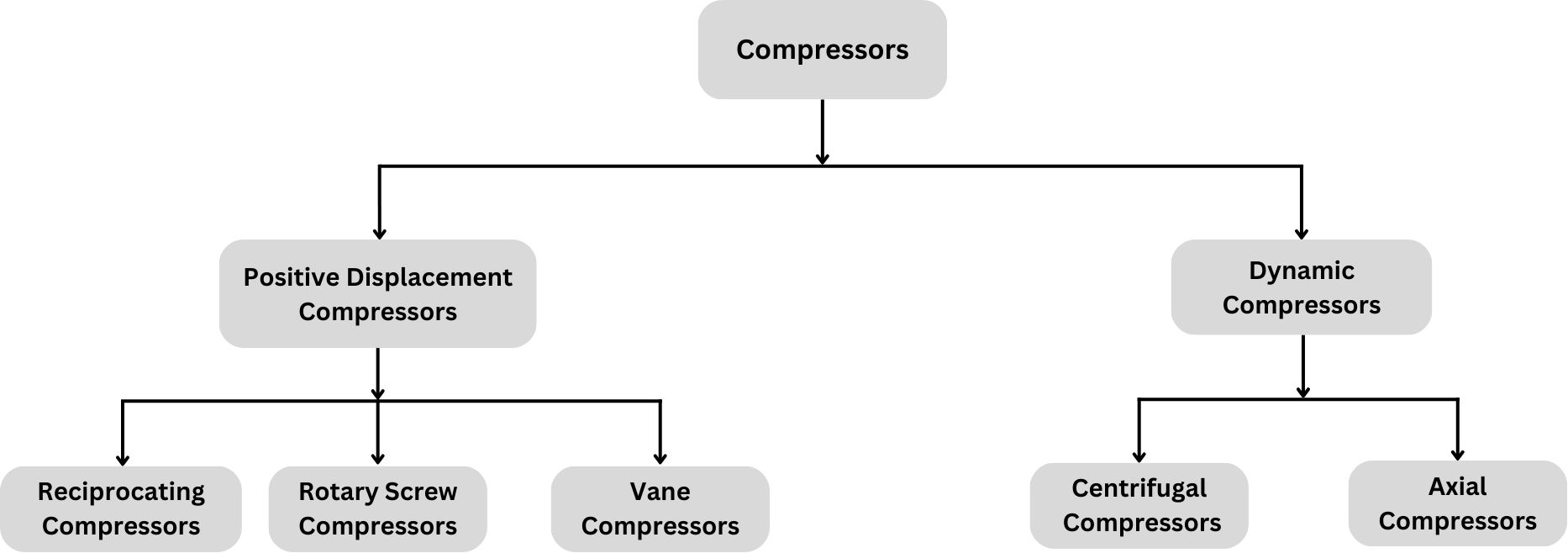

Classification of Air Compressors

- According to working

- Reciprocating Compressors

- Rotary Compressors

- According to number of stages

- Single Stage Compressors

- Multi-Stage Compressors

- According to action

- Single Acting Compressors

- Double Acting Compressors

- According to nature of installation

- Fixed

- Semi-Fixed

- Portable

- According to Cooling

- Water Cooled Compressors

- Air Cooled Compressors

Basic Terminology used in Compressor

- Inlet Pressure– It is the absolute pressure of ai entering in the compressor.

- Outlet/ Discharge Pressure– It is the absolute pressure of air exiting from the compressor.

- Compression Ratio/ Pressure Ratio– It is the ratio of discharge pressure to the inlet pressure. It is always greater than one because the discharge pressure is always greater than inlet pressure.

- Compressor Capacity– It is the volume of air delivered by the compressor. It is expressed in m3/s or m3/min.

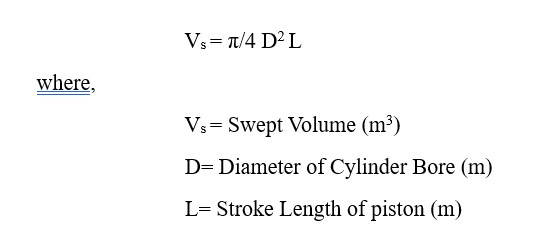

- Swept Volume– It is the volume of air sucked by the compressor during its suction stroke. It is given by

6. Free Air Delivery– It is the actual volume of air delivered by a compressor when reduced to normal temperature and pressure conditions. The capacity of a compressor is generally given in terms of free air delivery.

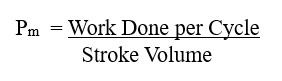

7. Mean Effective Pressure– It is the average pressure acting on the piston during the power stroke.

Single Stage Reciprocating Compressor

A single stage reciprocating air compressor consists of cylinder, piston, inlet and discharge valves. When the piston moves downwards (during outward or suction stroke), the pressure inside the cylinder falls below the atmospheric pressure. The inlet valve gets opened due to this pressure difference and air starts to enter the cylinder, until the piston completes the outward stroke.

Now, when the piston moves upwards (during inward or delivery stroke), the pressure inside the cylinder increases till it reaches the discharge pressure. At this stage, the discharge valve gets opened and air is delivered to the storage tank. When the delivery stroke is completed, a small quantity of air is left in the clearance space.

When the cycle starts again, this residual air starts to expand till its pressure falls below the atmospheric pressure. This pressure difference opens the inlet valve and fresh air enters the cylinder and the cycle is repeated. In this compressor, the suction, compression and discharge of air takes place in two strokes of the piston or one revolution of the crankshaft.

Note: In a double acting reciprocating air compressor, the suction, compression and delivery of air takes place on both sides of the piston. Therefore, this compressor supplies twice the volume of air supplied by a single acting reciprocating air compressor.

Multi Stage Compression

In a single stage reciprocating air compressor, the suction, compression and delivery of air takes place in a single stge. But sometimes, the air is required at a high pressure. For this, either we can employ a large pressure ratio in a single cylinder or compress the air in two or more cylinders in series. It has been observed that if we employ single stage compression for producing high pressure air (say 8 to 10 bar), it suffers the following drawbacks:-

- The size of the cylinder will be large.

- It is difficult to reject heat from the air in the small time available during compression.

- The temperature of air at the end of compression can be so high that it may heat up the cylinder head or burn the lubricating oil.

These drawbacks can be overcome by using two or more cylinders in series with intercooling arrangement between them. Such an arrangement is referred to as multi stage compression.

Advantages of Multi Stage Compression

- The work done by the compressor per cycle is reduced which reduces the total power required.

- The volumetric efficiency is increased.

- The size of the cylinder can be adjusted as per the requirement.

- It reduces the leakage losses considerably.

- It requires less amount of lubricant.

- It gives more uniform torque.

- It reduces the risk of explosion hazards.